|

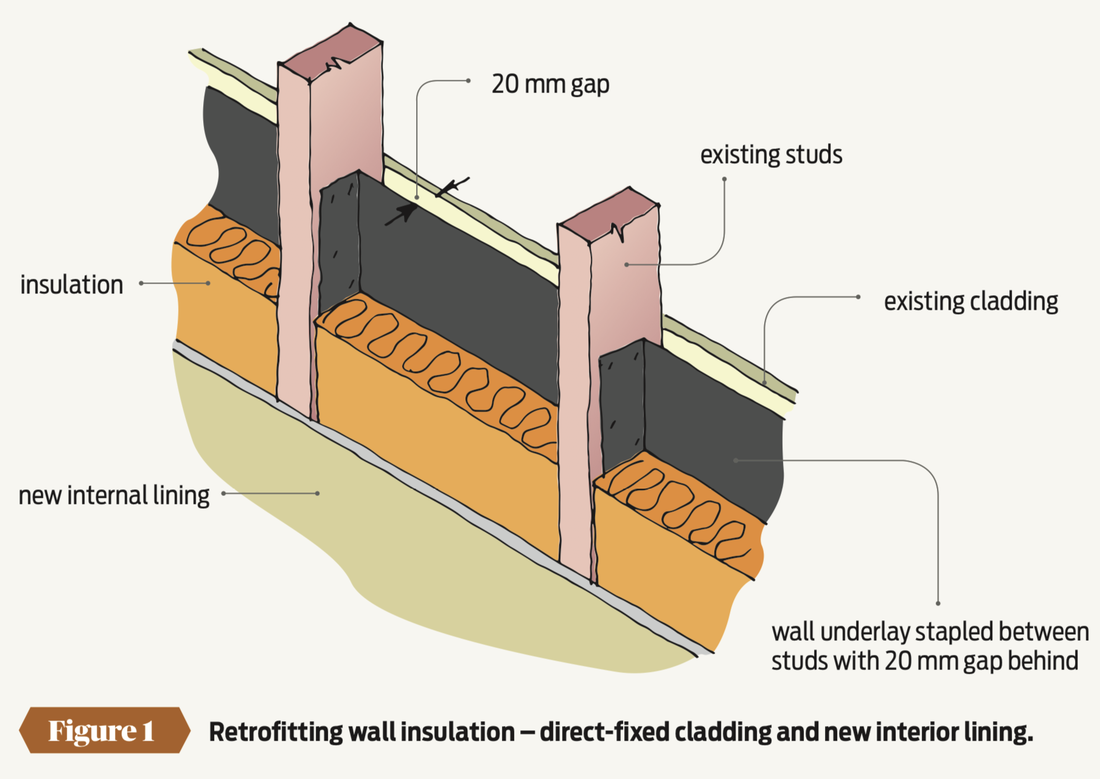

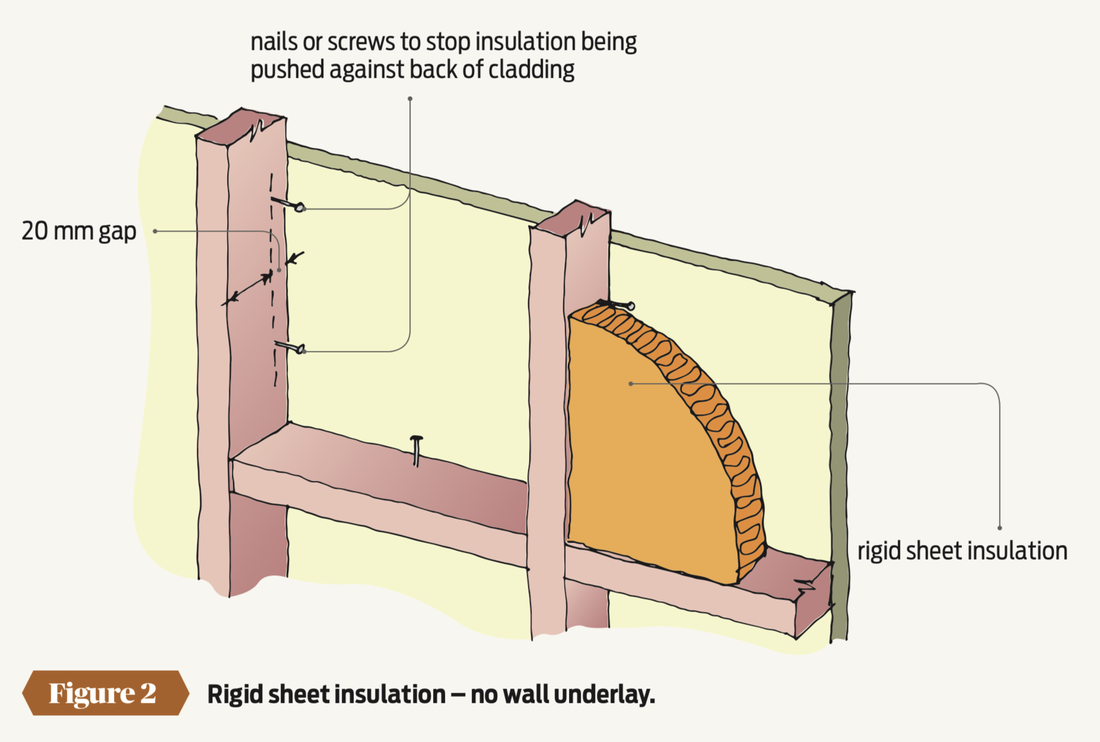

Insulation If you want a warm and healthy home, the first thing you need is efficient insulation. New Zealanders have come a long way from the days when the only home insulation was a rug over the knees on cold winter nights. All insulation works by trapping a layer of warm air within the building’s ceiling, underfloor and wall layers. The theory is straightforward but the practicalities are not. For a start, there are many different types of insulation on the market. Which product is best for you? They all have their pros and cons. Here’s a quick guide to the main types of home insulation on the New Zealand market. Fibreglass insulation This is the type most familiar to Kiwis. We’ve all seen the TV ads. It’s commonly made from recycled glass and offers excellent thermal performance, i.e. it traps heat more effectively than most other materials of the same thickness. On the downside, the glass fibres can be irritating to skin and eyes, while some people have concerns about the chemicals used to bond the fibres during manufacture. Polyester insulation This is often made from recycled plastic, such as PET drink bottles – an eco-friendly way to turn a waste product into a green insulation resource. It offers a good level of insulation performance, especially when installed as a large ‘blanket’ that rolls out to cover the entire roof space, including joists. This is an excellent way to minimise hidden heat loss. Harrisons Home Energy Solutions uses a polyester insulation brand that contains no chemical additives, unlike some fibreglass insulation products. Wool and wool blend insulation The stuff that keeps sheep warm can also be used to keep your home snug. It’s a natural product, which makes it pleasant to handle. Some brands of wool insulation are blended with resin and polyester to improve their effectiveness. Wool insulation does not work as well as some other types of insulation, so you may need to pay more to install a thicker layer. Foil insulation This is basically a special kind of paper coated with bitumen and aluminium foil. It relies on its shiny surface to reflect heat, so corrosion and dust can reduce its effectiveness over time. Foil used in isolation by itself is no longer accepted as complying with the Building Code for underfloor insulation. Foil Insulation - A ban on retrofitting or repairing foil insulation in residential properties came into force on 1 July 2016, to reduce the safety risks associated with installing this product. The ban, declared by the Chief Executive of MBIE, applies to the following building methods: •the installation of foil insulation into residential buildings with an existing electrical installation (retrofitting foil insulation) •the repair of foil insulation in residential buildings with an existing electrical installation (such as stapling ripped or damaged foil back onto the floor joists of a building). Polystyrene insulation Polystyrene foam is a good insulation material that’s used increasingly in new buildings. It’s a product of the petrochemical industry so is not particularly eco-friendly. However, it needs expert installation to ensure there are no gaps where heat can leak out – these will drastically reduce its effectiveness. Appendix A - Building Code performance settings for retrofitted insulation The Building Code performance criteria listed below are the relevant provisions of the Code to consider when assessing retrofitted wall insulation and whether it complies with the Code. Other Building Code performance criteria may also need to be considered for the building work associated with retrofitting insulation. For example, removing and reinstating structural wall linings or drilling holes through studs would require compliance with the Building Code clause B1.3.1. However the insulation itself does not need to comply with B1.3.1 as it is not part of the structural system of a building. It is useful to highlight upfront that the R-value of the retrofitted wall does not need to comply with the Building Code clause H1 Energy efficiency. There is no doubt that insulation is retrofitted to improve the wall R-value, but from a regulatory point of view retrofitting insulation is simply an alteration of the ‘thermal envelope’ described in H1.3.1(a). Unless the cladding, framing and linings of the wall are also reconstructed it is hard to consider how the ‘thermal envelope’ has been reconstructed, which would trigger compliance with H1.3.1(a). Therefore, the energy efficiency provisions of the Building Code are not mentioned in this section, which lists the performance criteria that insulation retrofits must comply with. Durability B2.3.1 Building elements must, with only normal maintenance, continue to satisfy the performance requirements of this code for the lesser of the specified intended life of the building, if stated, or: (a) the life of the building, being not less than 50 years, if: (iii) failure of those building elements to comply with the building code would go undetected during both normal use and maintenance of the building. Guidance: The durability requirement in the Building Code applies only to the extent that other Building Code performance criteria apply. The Building Code requires 50 year durability for building elements that are difficult to access or replace, or where failure of the building element to comply would go undetected. The durability requirement is not relevant to E2.3.6, which relates to moisture at the time of construction (see External moisture below). Common types of insulation are likely to meet the performance criteria F2.3.1 for a period of 50 years. Unusual types of insulation or very harsh environments may cause insulation to degrade over time and produce hazardous materials, though such a possibility could only be assessed on a case-by-case basis. External moisture E2.3.6 Excess moisture present at the completion of construction must be capable of being dissipated without permanent damage to building elements. Guidance: Moisture levels in most types of insulation should be at acceptable levels when installed. Moisture levels in insulation that is installed wet are likely to drop over time, provided the existing wall is vapour permeable and does not have pre-existing moisture problems. However, compliance of insulation that is installed wet with NZBC E2.3.6 will be difficult to assess given the variability in drying rates that occur and would need to be assessed on a case-by-case basis that could involve measurements. There is no acceptable solution for the dissipation of construction moisture from retrofitted insulation. Although not directly applicable, the Acceptable Solution E2/AS1 does provide a useful upper limit of 20% for timber moisture levels in timber framed walls13. The water content of some types of insulation that are installed wet is approximately 75% by weight, so the insulation must dry out after it is installed. The moisture content of adjacent timber framing should not exceed 20%, as suggested by the Acceptable Solution. A study of moisture levels in cavity walls show that drying rates vary widely depending on the type of wall construction, temperature and ventilation rate14. Drying times of 600 hours (i.e. 25 days) were measured for timber framing in south-facing, direct fixed walls with insulation installed in the framing cavities. In a separate study, moisture readings of timber framing in a brick veneer wall took approximately 60 days to drop below 20% moisture content after urea-formaldehyde foam was injected into the wall drainage cavity15. It was noted that the drying rate, which was measured in summer, would be significantly worse in winter and would likely result in south facing walls staying ‘wet’ throughout winter. Factors that will affect the drying potential of insulation in a cavity wall include,

Hazardous materials F2.3.1 The quantities of gas, liquid, radiation or solid particles emitted by materials used in the construction of buildings, shall not give rise to harmful concentrations at the surface of the material where the material is exposed, or in the atmosphere of any space. Guidance: Provided insulation is properly manufactured and installed, in accordance with manufacturers’ instructions, it is likely that it will comply with F2.3.1. There is no Acceptable Solution covering hazards associated with insulation. However, off-gassing and small airborne particles are the primary hazards to consider with insulation. A number of different chemicals are used in various types of insulation materials and in the binders that hold some types of insulation together. While such chemicals can be hazardous in high concentrations, generally the concentrations that are associated with thermal insulation are not high enough to be considered problematic. Formaldehyde is such an example, and while relatively common in many different building products it is generally not found in sufficiently high concentrations to be considered hazardous. WARNING: Retro - fitting wall insulation requires a council building consent.

8 Comments

|

BLOG

March 2024

Categories |

||||||||||||||||

LocationLocated on Grahams Road, we are right in the centre of Christchurch, making it a lot easier on the whole for people to reach out to us for help at any time during the day. |

|

RSS Feed

RSS Feed